Figure 1: Smart manufacturing environment demonstrating data-driven CNC milling machine selection process, featuring real-time performance metrics and international quality standards implementation.

Introduction

In today’s competitive manufacturing landscape, companies often face significant challenges due to improper CNC milling machine selection. Organizations in sectors like automotive and aerospace frequently encounter cost overruns, diminished productivity, and quality issues when choosing equipment based solely on initial price or superficial features. The root causes include a lack of understanding of technical variations among machines, oversight of critical industry standards such as precision tolerances, and reliance on outdated selection methods that prioritize short-term savings over long-term value.

This article provides a research-based framework to help decision-makers scientifically evaluate CNC milling options, integrating authoritative standards like ASME Y14.5 and ISO 9001 to optimize the selection process. By examining key factors such as machine rigidity, application-specific needs, and certification requirements, readers will gain actionable insights to enhance manufacturing efficiency and avoid common pitfalls that can lead to substantial financial losses.

What Are the Fundamental Criteria for Selecting a CNC Milling Machine in High-Stakes Industries?

Selecting the right CNC milling machine requires a holistic approach beyond price considerations. In industries like automotive and aerospace, where precision is paramount, decision-makers must prioritize criteria such as tolerance capabilities, machine stiffness, and compatibility with industry standards. For instance, adherence to ASME Y14.5 dimensioning and tolerancing standards ensures that parts meet exact specifications for form, fit, and function, reducing errors in production.

1. Accuracy and Tolerance Requirements

CNC machines must achieve tight tolerances (e.g., ±0.005mm) to prevent costly rework, referencing standards like ASME Y14.5 for geometric dimensioning. The relationship between tolerance and cost is exponential – tighter tolerances demand more precise machinery, slower feed rates, and increased inspection times. Research indicates that implementing strategic tolerance design based on functional needs can lead to up to 40% cost savings while maintaining quality standards.

2. Rigidity and Stability Considerations

High-stakes applications demand robust machine frames to minimize vibration and maintain precision under heavy loads. Machine rigidity directly impacts surface finish quality and dimensional accuracy, particularly when machining challenging materials like titanium or Inconel. A machine with inadequate rigidity may cause deflection in aerospace alloys, resulting in scrap rates exceeding 15% and significant production delays.

3. Application-Specific Alignment

Different industries have unique requirements that must guide CNC milling machine selection. Automotive production typically demands high-speed machining capabilities for volume production, while aerospace applications often require multi-axis capabilities for complex geometries. Understanding these distinctions helps manufacturers avoid the common pitfall of selecting machines based on generic specifications rather than actual operational needs.

How Does CNC Milling Technology Enhance Precision and Efficiency in Automotive Manufacturing?

CNC milling technology revolutionizes automotive manufacturing by enabling high-precision component production with minimal waste. Studies show that implementing advanced CNC milling systems can reduce scrap rates by up to 30% and accelerate time-to-market for new vehicle models. The technology’s ability to maintain consistent quality across production runs makes it indispensable for modern automotive manufacturing.

1. Complex Geometry Handling Capabilities

Modern CNC machines effortlessly produce intricate parts like engine blocks, transmission components, and suspension elements that traditional methods cannot achieve. The 5-axis CNC milling technology, in particular, allows for complex contour machining without multiple setups, significantly reducing production time and improving accuracy. This capability supports the automotive industry’s trend toward lightweighting and component integration.

2. Consistency and Repeatability Benefits

With automated controls and digital precision, every part meets identical specifications – crucial for mass production in the automotive sector. The integration of ISO 9001 certified quality management systems ensures that CNC milling processes maintain consistency across production batches, reducing variations that can lead to assembly issues or warranty claims.

3. Integration with Lean Manufacturing Principles

CNC milling technology aligns perfectly with lean manufacturing methodologies by reducing setup times, minimizing material waste, and enabling just-in-time production. Automotive manufacturers implementing advanced CNC solutions report 20-25% improvements in overall equipment effectiveness (OEE), translating to significant competitive advantages in a margin-sensitive industry.

What Are the Key Differences Between Vertical and Horizontal CNC Milling Machines, and When to Choose Each?

Understanding the distinctions between vertical and horizontal CNC milling machines is indeed critical for optimizing production efficiency and cost-effectiveness, as each configuration offers unique advantages tailored to specific applications and production scenarios. For a more detailed technical comparison and practical selection guidance, you may find our specialized analysis on vertical vs. horizontal CNC milling machine configurations helpful, which includes real-world case studies and decision-making frameworks.

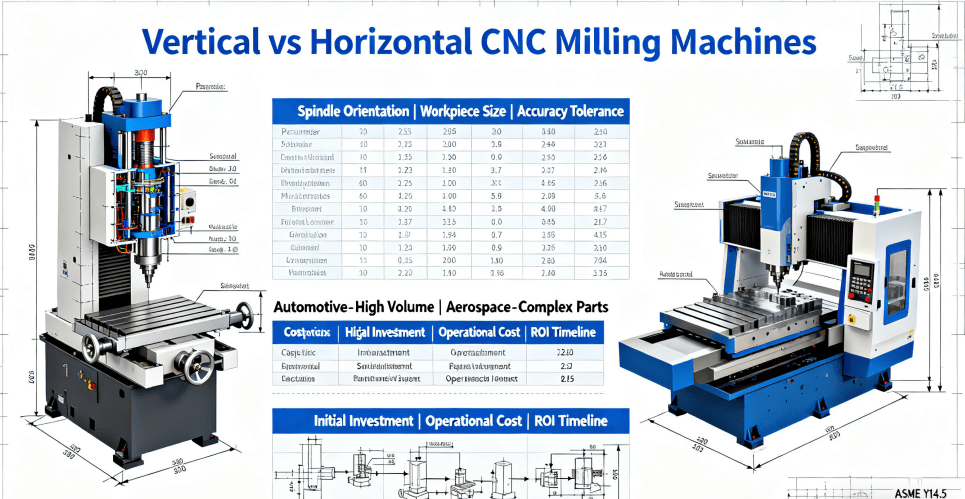

Figure 2: Engineering analysis of CNC milling machine configurations, providing decision-making framework based on technical specifications, cost considerations, and industry application requirements.

l Structural Design and Operational Characteristics: Vertical CNC mills feature a vertically oriented spindle that’s ideal for planar machining and simpler parts, offering easier setup and operator accessibility. In contrast, horizontal CNC mills have a horizontal spindle orientation that provides better chip evacuation, enhanced stability for heavy-duty machining, and capability for simultaneous multi-sided machining. The structural differences directly impact machining capabilities, with horizontal machines typically offering higher productivity for complex components.

l Application Suitability and Production Scenarios: Choose vertical milling machines for prototyping, mold making, or plate-based work where single-face machining predominates. These machines typically have lower initial costs (starting from $100,000) and are ideal for small to medium batch sizes. Horizontal milling machines excel in high-volume production of complex, multi-sided components like automotive engine blocks or aerospace structural elements. While requiring higher initial investment, they offer superior efficiency for mass production through reduced setup times and simultaneous machining capabilities.

l Cost Implications and Return on Investment: The selection between vertical and horizontal configurations should consider total cost of ownership rather than just initial purchase price. Vertical mills generally have lower upfront costs but may incur higher per-part expenses in high-volume production due to longer cycle times. Horizontal mills, despite higher initial investment, typically deliver lower per-unit costs in mass production scenarios through faster cycle times and reduced labor requirements. Proper selection can impact overall production costs by 20-30%.

How Can Manufacturers Leverage Advanced CNC Milling Features to Reduce Operational Costs?

Advanced features in modern CNC milling machines offer significant opportunities for operational cost reduction while maintaining or even improving quality standards. Manufacturers who strategically invest in these technologies can achieve substantial competitive advantages in today’s demanding market environment.

1.Multi-Axis Machining Capabilities: 5-axis CNC milling technology enables complex part production in a single setup, eliminating multiple fixturing and reducing cumulative errors. This capability can reduce production time by up to 60% for complex components while improving dimensional accuracy. The reduction in setup changes also decreases labor requirements and tooling costs, contributing to overall cost efficiency. Industries dealing with complex geometries, such as aerospace and medical device manufacturing, particularly benefit from these advancements.

2. Automation and Smart Manufacturing Integration: Modern CNC milling machines with automated tool changers, pallet systems, and robotic integration enable lights-out manufacturing capabilities. These features reduce labor costs, increase machine utilization rates, and ensure consistent quality through reduced human intervention. The integration of IoT sensors and predictive maintenance algorithms further enhances operational efficiency by minimizing unplanned downtime and extending equipment lifespan.

3. Energy Efficiency and Sustainable Practices: Newer CNC milling machines incorporate energy-efficient drives, optimized cooling systems, and power management features that significantly reduce electricity consumption. Combined with sustainable manufacturing practices aligned with ISO 14001 standards, these improvements can lower energy costs by 15-25% while reducing environmental impact. The focus on sustainability also opens opportunities with environmentally conscious clients and may qualify for various green manufacturing incentives.

What Role Do Industry Certifications Like IATF 16949 Play in Ensuring CNC Milling Quality?

Industry certifications serve as critical indicators of a manufacturer’s commitment to quality and continuous improvement. In precision machining sectors, these certifications provide assurance that processes meet internationally recognized standards for reliability and consistency.

Quality Management System Certification

ISO 9001 certification forms the foundation of a robust quality management system, ensuring standardized processes, documented procedures, and continuous improvement mechanisms. For CNC milling operations, this certification demonstrates a systematic approach to quality control that reduces defects and enhances customer satisfaction. Manufacturers with ISO 9001 certification typically experience 25-30% fewer quality incidents compared to non-certified operations.

Industry-Specific Certification Requirements

IATF 16949 represents the automotive industry’s specific quality management requirements, emphasizing preventive approaches, defect reduction, and supply chain management. Similarly, AS9100D certification addresses the rigorous demands of the aerospace industry, focusing on safety, traceability, and risk management. These sector-specific certifications ensure that CNC milling suppliers understand and can meet the unique challenges of high-stakes manufacturing environments.

Certification Impact on Risk Mitigation

Certified CNC milling processes significantly reduce risks associated with part failure, production delays, and compliance issues. The rigorous audit processes required for maintaining certifications ensure that quality systems remain effective and responsive to changing requirements. This proactive approach to quality management helps prevent costly recalls and reputation damage, particularly in safety-critical industries like automotive and aerospace.

How to Evaluate CNC Milling Machine Manufacturers for Long-Term Partnership?

Selecting the right manufacturing partner requires a comprehensive evaluation process that considers technical capabilities, quality systems, and cultural alignment. The chosen partner should demonstrate the ability to support both current needs and future growth objectives.

Technical Capability Assessment

Evaluate potential partners based on their equipment portfolio, technological capabilities, and industry experience. Look for manufacturers with comprehensive CNC machining services including multi-axis capabilities, advanced metrology equipment, and material expertise. The ability to provide design for manufacturability (DFM) feedback early in the design process represents particular value, as it can identify potential manufacturing challenges before they become costly problems.

Quality System Verification

Verify that potential partners maintain relevant certifications such as ISO 9001, IATF 16949, or AS9100D based on your industry requirements. Review their quality documentation, inspection reports, and continuous improvement records to assess the effectiveness of their quality systems. Partners with robust quality management typically demonstrate lower defect rates and higher process consistency.

Service and Support Evaluation

Consider the manufacturer’s approach to customer service, technical support, and problem resolution. Reliable partners offer comprehensive after-sales support, preventive maintenance programs, and responsive communication channels. The ability to provide rapid prototyping services, flexible production scheduling, and engineering support represents significant value in dynamic manufacturing environments.

Conclusion

Selecting the right CNC milling machine represents a strategic decision with far-reaching implications for manufacturing efficiency, product quality, and competitive positioning. By moving beyond simplistic price comparisons to consider factors like tolerance capabilities, machine configuration, advanced features, and supplier certifications, decision-makers can avoid up to 25% cost overruns while significantly boosting operational efficiency.

This guide demonstrates the importance of a holistic approach that integrates technical standards like ASME Y14.5 for precision, quality management systems like ISO 9001 for consistency, and industry-specific certifications for compliance. The strategic evaluation of CNC milling machine manufacturers based on technical capabilities, quality systems, and partnership potential ensures long-term success in increasingly competitive manufacturing landscapes.

Embracing these research-driven strategies enables manufacturers to make informed decisions that balance immediate operational needs with long-term strategic objectives, ultimately driving sustainable growth and market leadership in precision manufacturing.

FAQs

Q: What is the average lead time for CNC milling projects?

A: Lead times vary based on complexity, but standard CNC milling projects typically take 3-7 days for prototyping and 7-15 days for production runs. Advanced planning and DFM optimization can help accelerate these timelines while maintaining quality standards.

Q: How does vertical CNC milling differ from horizontal in terms of cost?

A: Vertical CNC milling machines generally have lower initial costs (starting from $100,000) and are ideal for small batches or simpler components. Horizontal CNC milling machines require higher investment but offer greater efficiency for mass production, reducing per-unit costs over time through faster cycle times and reduced labor requirements.

Q: What materials are commonly used in CNC milling for aerospace applications?

A: Aerospace CNC milling typically utilizes high-performance materials including titanium alloys, aluminum composites, and high-temperature resistant superalloys. These materials meet strict standards like AS9100D for precision and durability in critical components subjected to extreme operating conditions.

Q: Can CNC milling handle complex geometries with tight tolerances?

A: Yes, advanced CNC milling technology supports complex geometries with tolerances up to ±0.005mm. 5-axis CNC machining capabilities, combined with rigorous quality checks and CMM inspection, make modern CNC milling suitable for intricate parts in medical, automotive, and aerospace applications.

Q: How do certifications like ISO 9001 impact CNC milling quality?

A: ISO 9001 certification ensures consistent quality management processes throughout CNC milling operations. Implementation of standardized procedures, regular audits, and continuous improvement practices typically reduce defects by 25-30% while enhancing overall process efficiency and customer satisfaction.

Author Bio

This article was developed by the precision manufacturing specialists at LS Manufacturing, an industry-leading organization certified to ISO 9001, IATF 16949, and other international standards. The company’s engineering team supports clients across sectors such as automotive, aerospace, and medical devices with advanced CNC milling solutions, design for manufacturability (DFM) guidance, and end-to-end project management.

For organizations seeking to optimize production efficiency or explore new opportunities in precision machining, the team offers actionable insights and customized support. Visit their dedicated service page to learn more or request a personalized consultation.