In today’s fast-paced electronics industry, the demand for high-performance and high-reliability electronic assemblies is stronger than ever. Whether it’s a life-saving medical device, a satellite communication system, or a precision industrial controller, one thing is certain — the reliability of the final product begins with the precision of the manufacturing process.

At the heart of modern electronics production lies Surface Mount Technology (SMT), the cornerstone of PCBA (Printed Circuit Board Assembly). Let’s explore how SMT plays a critical role in ensuring reliability at every stage of the PCBA manufacturing process.

What Is SMT in PCBA Manufacturing?

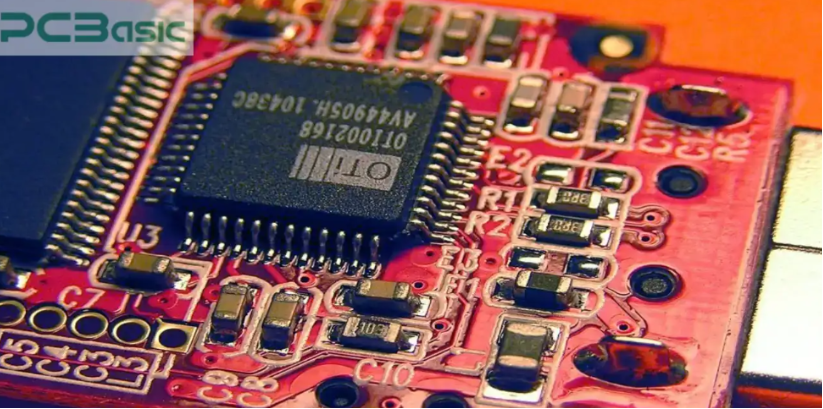

SMT (Surface Mount Technology) is the process of mounting electronic components directly onto the surface of a printed circuit board (PCB), unlike traditional through-hole methods. SMT enables smaller, lighter, and more complex PCBs with higher component density and greater performance.

In a typical PCBA manufacturing workflow, SMT is the front-line process that determines the success of all subsequent stages. It includes:

- Solder paste printing

- Component placement

- Reflow soldering

- Optical and X-ray inspection

Each step is vital — and any small error can cascade into a major quality failure down the line.

Step-by-Step: How SMT Ensures High Reliability

1. Solder Paste Printing Accuracy

It all starts with precision. The correct deposition of solder paste onto each pad is essential for forming reliable solder joints. High-quality stencils and SPI (Solder Paste Inspection) systems help ensure:

- Paste volume within tolerance (typically ±15%)

- Accurate alignment on pads

- No bridging, insufficient paste, or collapse

This stage directly impacts solder joint strength and overall electrical performance.

2. High-Speed, High-Precision Component Placement

Using automated pick-and-place machines, components are mounted at lightning speed with micron-level accuracy. To maintain reliability:

- Placement accuracy must be within component specifications

- Orientation must match polarity and footprint

- Gentle handling is required to avoid micro-cracks in MLCCs or fragile packages

This is particularly critical in high-reliability industries like aerospace and automotive.

3. Controlled Reflow Soldering Profiles

The reflow process melts the solder paste to form permanent joints. A well-controlled thermal profile ensures:

- Proper wetting of solder on both pad and lead

- Avoidance of voids, cold solder, or tombstoning

- Uniform heating across the board to prevent thermal stress

Every product’s reflow profile must be tailored based on board material, component types, and solder paste characteristics.

4. In-Line AOI and X-ray Inspection

Reliability is confirmed through rigorous inspection:

- AOI (Automated Optical Inspection) checks for solder defects, misalignment, missing or wrong components

- AXI (Automated X-ray Inspection) reveals hidden defects like voids, solder bridging, or incomplete joints in BGAs and QFNs

These tools ensure 100% inspection coverage and early defect detection — vital for high-reliability products.

Why SMT Precision Matters in High-Reliability PCBA

For industries that demand IPC Class 3 compliance — such as aerospace, medical, and military — the margin for error is near zero. SMT is the gatekeeper of that quality.

At PCBasic, we’ve implemented strict SMT process controls, including:

- Class 3-compliant SPI inspection standards

- Real-time MES system data tracking

- Tailored solder profiles for each assembly type

- Continuous improvement via SPC (Statistical Process Control)

Even for small and medium production batches, we apply the same rigor — because we believe reliability should never depend on quantity.

Conclusion

SMT is not just a process — it’s a foundation. Every reliable electronic product owes its performance to the accuracy and consistency of SMT assembly.

From solder paste to inspection, from prototypes to production, SMT in PCBA manufacturing ensures high reliability at every step. And in today’s world, where electronics must be smarter, faster, and more dependable than ever — that reliability is non-negotiable.