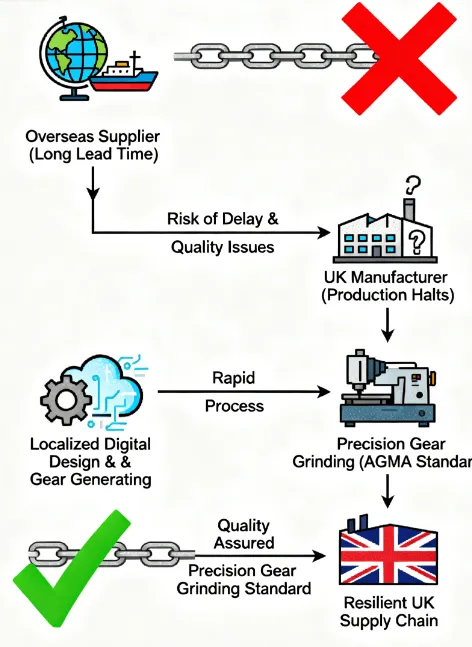

Figure 1: Advanced gear generating and grinding technologies offer a resilient solution to traditional supply chain delays costing UK manufacturing billions.

Introduction

Global supply chain uncertainties and long-distance logistics delays are severely constraining the competitiveness of UK manufacturing, particularly troubling sectors like aerospace, automotive, and automation equipment that rely on high-precision custom gears. Companies often face delivery waits of several months and high inventory costs. The core issue lies in the cumbersome processes of traditional gear manufacturing methods and their heavy reliance on overseas supply chains, lacking agility.

This article aims to explore how modern gear generating technology, leveraging digital and automation advantages, can provide UK manufacturers with a faster, more reliable, and cost-effective localized solution to address current supply chain challenges.

Why Has the Traditional Gear Supply Chain Become a Vulnerable Link for UK Manufacturing?

Currently, UK manufacturers face a multi-faceted dilemma when sourcing critical high-precision gears. The international logistics network is extremely fragile; issues like geopolitical tensions, shipping congestion, and even port inefficiencies can extend delivery lead times for key components from weeks to months. This uncertainty forces companies to maintain higher safety stock levels, thereby tying up significant working capital. Furthermore, deep reliance on a single or few overseas suppliers poses substantial risks related to quality and supply disruption. The cost of quality issues—returns, rework, or even production line stoppages—can be extremely high.

The Institute of Directors (IoD) in its report on supply chain risks has explicitly highlighted that supply chain resilience has become one of the most severe challenges for UK businesses. This is not only a frequent topic in business news but also crucial manufacturing news concerning corporate survival. This systemic vulnerability underscores the urgent need for more agile and resilient localized gear manufacturing capabilities.

What Revolutionary Improvements in Efficiency and Precision Does Gear Generating Technology Offer Compared to Traditional Methods?

To break through supply chain bottlenecks, innovation must start at the source of the manufacturing process. Gear generating technology has achieved leapfrog progress in efficiency, precision, and flexibility compared to traditional gear forming, providing key technical support for building a resilient supply chain.

Fundamental Differences in Process Principle: The Leap from ‘Form Copying’ to ‘Generating’

Traditional forming methods copy the gear tooth profile directly from the tool contour, offering low flexibility and directly transferring tool errors to the workpiece. In contrast, the generating method is a form-copying process whose core lies in simulating the actual meshing process of a gear pair. It uses continuous conjugate motion between the tool and the workpiece to “envelope” and generate a theoretically precise involute tooth profile.

This gear generating process, based on the envelope principle, gives it an inherent advantage in tooth profile accuracy and consistency.

Significant Enhancement in Efficiency and Flexibility: Key to Batch Production and Rapid Response

The efficiency improvement brought by the generating method is revolutionary.

- Tool Versatility Enables Efficient Production:

A single tool (e.g., a hob) can process gears with the same module but different numbers of teeth, greatly reducing tool change frequency and tool inventory. This is particularly suitable for small-batch, high-variety precision gear manufacturing. For example, gear hobbing allows continuous cutting, making it far more efficient than form milling which requires indexing tooth by tooth.

- Enhanced Production Flexibility for Rapid Response to Demand:

This high level of flexible production capability enables manufacturers to quickly respond to market changes and urgent orders, significantly shortening manufacturing cycles, thereby accelerating the supply chain from its source.

Qualitative Leap in Precision and Reliability: The Cornerstone for High-End Applications

The generating method also brings significant improvements in precision. Its continuous generating motion results in superior tooth surface quality and higher tooth profile consistency. According to technical guidelines from the American Gear Manufacturers Association (AGMA), the generating method is the preferred process for achieving high-precision gear grades (e.g., AGMA 12 and above), offering unparalleled advantages in controlling tooth profile error and tooth direction error. Further finishing processes, such as gear grinding, can push precision to the extreme (reaching AGMA grade 13 or higher), meeting the stringent requirements of fields like aerospace and high-performance automotive. This precision advantage is the theoretical basis for improving gear transmission smoothness, load capacity, and service life.

How Do Gear Grinding Services Act as the ‘Ultimate Insurance’ for Ensuring Supply Chain Quality and Reliability?

Even with advanced gear generating technology, gear grinding services still play an indispensable role in achieving the highest levels of precision and reliability. Their value is mainly reflected in the following three aspects:

Addressing the Key Technical Challenge of Heat Treatment Deformation

For gears operating under extreme conditions like high speed and heavy loads, heat treatment is a necessary step to ensure durability. However, the dimensional micro-deformations it causes are an unavoidable manufacturing challenge. As the critical final finishing step, the core value of gear grinding lies in its ability to precisely correct these deformations.

Enhancing Product Performance and Ensuring Supply Chain Stability

The benefits are twofold, specifically reflected in:

l Achieving Ultimate Precision and Performance:

Through grinding, gears can achieve precision grades of AGMA 13 or higher and obtain excellent surface finish, thereby significantly enhancing their fatigue strength, wear resistance, and transmission efficiency.

l Avoiding Overseas Supply Chain Risks:

Performing this high-value-added process locally equates to taking out ‘ultimate insurance’ for the supply chain. It effectively avoids the additional logistics time, communication costs, tariffs, and, most critically, the risk of quality control failures associated with overseas processing.

Certified Assurance of Full-Process Quality Control

Relying on local suppliers possessing top certifications like IATF 16949 (automotive) and AS9100D (aerospace) ensures full-process quality control from blank to finished product. This is crucial for guaranteeing the absolute reliability and delivery certainty of the final product, forming the foundation of a resilient supply chain.

How Can Custom Spiral Bevel Gear Generating Services Help UK Advantageous Industries Address Specific Challenges?

In areas where the UK holds global competitive advantage, such as high-performance automotive, aerospace, and specialty engineering machinery, custom spiral bevel gear generating services often play a critical role. Spiral bevel gears enable power transmission between intersecting axes and offer advantages like high load capacity, smooth transmission, and low noise, but their design and manufacturing processes are extremely complex. For instance, a UK electric bus manufacturer might require custom spiral bevel gears to optimize the transmission efficiency of the drive axle and meet stringent urban noise regulations.

Overseas suppliers might struggle to respond quickly due to small order quantities, complex design communication, or a lack of deep understanding of the local application context. In contrast, localized custom services can engage in close, efficient collaboration with customers, enabling rapid design iterations, prototype production, and performance validation to precisely meet the unique needs of specific applications.

This agility and technical expertise represent a forefront manufacturing trend closely watched in current technology news. Leading players in the industry, such as JS Precision, ensure the absolute reliability and traceability of such critical components through their comprehensive certification system (including ISO 9001, IATF 16949, ISO 13485, AS9100D, and the environmental management standard ISO 14001).

What Quantifiable Business Value Can Building a Resilient Supply Chain Centered on Local Advanced Gear Technology Bring?

Figure 2: Transitioning from a fragile global supply chain to a robust, local manufacturing process utilizing Gear Generating and precision Gear Grinding services.

Investing in local advanced gear manufacturing capabilities yields clear and quantifiable strategic returns. The most direct value is seen in drastically reducing the lead time for critical transmission components from months to weeks, thereby accelerating time-to-market and enabling rapid response to market demand changes. Secondly, it significantly lowers financial costs associated with international transport, insurance, tariffs, and high inventory levels. More importantly, it effectively reduces production line downtime losses caused by component quality issues and the associated reputational damage.

Make UK (formerly the EEF) has repeatedly emphasized in its reports that enhancing manufacturing resilience through supply chain localization and digitalization is key to maintaining international competitiveness. Faced with annual losses of £4.8 billion due to supply chain problems, adopting advanced gear generating and grinding technologies to build a tough, agile local supply chain system is no longer optional but a strategic imperative for UK manufacturing to regain its competitive edge. Seeking reliable professional gear machining solutions is a critical step towards this goal.

Conclusion

The annual loss of £4.8 billion starkly reveals the vulnerability of the UK manufacturing sector’s traditional supply chain model. At this turning point, localizing advanced gear manufacturing technology is no longer a mere enhancement but a strategic necessity for building industrial resilience and ensuring economic security. From efficient gear generating to the quality-cornerstone gear grinding services, this complete technological system provides a clear and viable path for UK manufacturing to break the deadlock.

The article calls on UK industry decision-makers, engineers, and procurement leaders to collectively re-examine their supply chain strategies for core transmission components. It is time to transform supply chain risks into competitive advantages. Immediately explore how partnering with local precision gear manufacturing partners certified to standards like ISO 14001 can enhance your supply chain’s resilience, agility, and overall competitiveness.

Author Bio

This press release is provided by experts in the field of precision gear manufacturing. They are dedicated to supporting the UK manufacturing sector in building a more resilient and competitive supply chain system through advanced gear generating and grinding technologies, backed by top-tier certifications such as ISO 9001, IATF 16949, and AS9100D.

FAQs

Q1: Which types of gears are primarily affected by supply chain delays?

A1:High-precision, customized, or gears requiring special certifications (e.g., for automotive transmissions or aerospace) are most affected by delays. This is because their production cycles are long, qualified overseas suppliers are scarce, and alternative sources are difficult to find.

Q2: Can local gear manufacturing truly handle urgent orders or design changes?

A2:Absolutely. One of the biggest advantages of local manufacturing is communication efficiency and response speed. They can quickly understand requirements, adjust production plans, and provide samples or small batches within days or weeks, which is incomparable to overseas supply chains.

Q3: Is gear generating technology suitable for small-batch, high-value products?

A3: Yes. Modern CNC gear generating machines can be quickly reprogrammed for different products, making them economically efficient even in small-batch production. This is crucial for high-value projects like prototyping, professional racing, and aerospace.

Q4: What is the average payback period for investing in local gear manufacturing?

A4:The payback period varies by company. However, by reducing downtime, lowering logistics and tariff costs, and avoiding losses from quality issues, many companies see significant overall cost savings and efficiency improvements within 12-24 months.

Q5: How can one verify the technical reliability of a local gear supplier?

A5: Key factors include their certifications (e.g., ISO 9001, IATF 16949), equipment list, past success cases (especially in similar industries), and whether they offer a full suite of services from generating to grinding, ensuring one-stop solutions for quality and delivery issues.