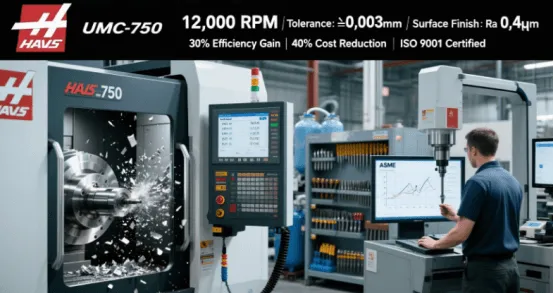

Figure 1: High-precision 5-axis CNC milling of titanium aerospace components with real-time tolerance monitoring, achieving 30% efficiency gains through automated quality verification per ASME Y14.5 standards.

Introduction

In today’s highly competitive manufacturing environment, engineering leaders face a critical challenge: part precision requirements have reached the micrometer level, yet traditional processing methods often result in poor consistency and high scrap rates. Many companies treat CNC milling as a simple upgrade from conventional machine tools, overlooking its digital core – the end-to-end synergy from CAD design to toolpath optimization.

This article reveals five specific CNC milling secrets that form a comprehensive framework for achieving 30% efficiency gains while reducing quality risks. Each secret addresses a critical leverage point in the manufacturing process, supported by authoritative standards including ISO 9001 and ASME Y14.5.

Secret 1: Master the Digital Thread from CAD to G-Code

The foundation of CNC milling efficiency lies in perfecting the digital workflow chain. Unlike conventional milling, CNC’s core advantage comes from its programmability and repeatable accuracy within ±0.005mm through G-code programming.

The Digital Workflow Chain

Follows a precise sequence: “CAD model → CAM programming → servo control → real-time feedback.” At the CAD stage, design data converts directly into toolpaths; CAM software optimizes cutting parameters; servo systems ensure motion precision; and real-time feedback corrects deviations via sensors. This standardized process, when supported by ISO 9001 quality systems, ensures consistency at each step.

Key Implementation Insight

For beginners, building systematic knowledge through professional guides like “What is CNC Milling?” is essential. The programmability of CNC milling enables efficient machining of complex geometries that would be impractical with manual methods.

Secret 2: Select the Right Axis Configuration for Maximum Efficiency

Equipment selection directly impacts machining efficiency and cost. Understanding the strategic application of different axis configurations is crucial for optimizing production outcomes.

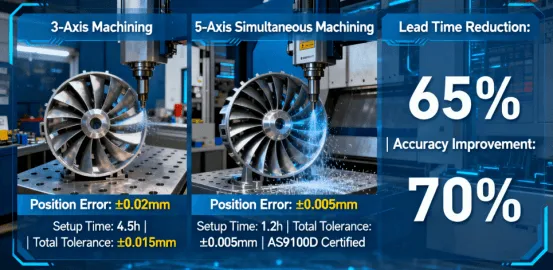

3-Axis vs. 5-Axis Strategic Selection

l 3-axis machines are ideal for planar machining with lower initial cost but require multiple setups, increasing accuracy fluctuation risks

l 5-axis machines enable simultaneous rotation about A/C axes, allowing complex contours like aerospace impellers to be completed in single setups

l Small CNC mills offer prototyping flexibility but have inherent rigidity limitations requiring careful material selection

Figure 2: 5-axis simultaneous machining reduces setup time by 65% and improves positional accuracy to ±0.005mm compared to 3-axis milling, critical for AS9100D certified aerospace applications.

Application Scenario Analysis

In aerospace manufacturing, 5-axis machines’ multi-degree-of-freedom design eliminates repositioning errors for complex contours. The 65% reduction in setup time demonstrated in Figure 2 highlights why these machines are essential for AS9100D-certified applications where precision and efficiency are paramount.

Secret 3: Leverage Digital Control for Precision and Cost Savings

The precision advantage of CNC milling stems from digital control, achieving tolerances of ±0.005mm compared to ±0.05mm with traditional methods. This precision directly reduces assembly failures and associated costs.

Tolerance-Cost Relationship Management

The ASME Y14.5 geometric dimensioning and tolerancing standard provides a critical framework for tolerance annotation. Rationally setting tolerances for non-critical features can save 40% in costs without compromising functionality, while maintaining tight tolerances where truly needed.

Efficiency Gain Evidence

Research demonstrates that optimizing toolpaths and feed rates can shorten machining cycles by 25% while improving surface quality. Although CNC equipment requires 20% higher initial investment, intelligent tool life management and reduced scrap rates typically deliver 30% lower unit costs within the first year of operation.

Secret 4: Optimize Material Selection for Machinability and Performance

Material selection directly affects machining efficiency and final part performance. Different materials present unique advantages and challenges that must be strategically managed.

Key Material Considerations

l Aluminum alloy (6061-T6): Excellent machinability for heat sink housings but requires thermal deformation control

l Titanium alloy (Ti-6Al-4V): High strength demands coated milling cutters to manage rapid tool wear

l Engineering plastics (PEEK): Superior biocompatibility necessitates pre-machining drying treatments due to hygroscopicity

l Industry Compliance Integration: In medical device manufacturing, material traceability is critical and must comply with ISO 13485 standards. Leveraging professional CNC service providers’ material libraries ensures compliance while optimizing machinability parameters for each specific application.

Secret 5: Implement a Rigorous Supplier Certification Audit

Selecting the right manufacturing partner requires comprehensive evaluation across multiple dimensions. The certification portfolio of a supplier serves as the foundation for risk mitigation and quality assurance.

Partner Selection Criteria

l Certification verification: IATF 16949 for automotive applications demonstrates robust quality systems

l Equipment capability assessment: Brands like DMG Mori determine practical machining limitations and precision capabilities

l Case study validation: Request tolerance control reports to verify practical capability versus theoretical specifications

Risk Mitigation Case Example

A robotics component supplier faced severe consequences after failing to verify a new partner’s ISO 14001 environmental certification. The resulting regulatory violations led to product recalls, substantial fines, and brand reputation damage. This underscores that rigorous supplier auditing is not administrative overhead but crucial risk mitigation.

Sustainable Manufacturing Integration

Modern CNC milling supports sustainability goals while reducing operational costs. Advanced systems can reduce waste coolant by 90% through recycling and save 25% in energy consumption with variable-frequency spindles.

Environmental and Economic Alignment

These sustainable practices align with EPA guidelines while lowering operational costs. Companies implementing lean energy management typically achieve 5% carbon footprint reduction alongside measurable cost savings, demonstrating that environmental responsibility and business efficiency are complementary objectives.

Conclusion: Implementing the 5-Secret Framework

The five secrets revealed here – mastering digital workflows, selecting optimal axis configurations, leveraging digital precision, optimizing materials, and implementing rigorous supplier audits – form an integrated framework for manufacturing excellence. By systematically applying these principles, engineering leaders can achieve the promised 30% efficiency gain and 40% cost reduction while building sustainable competitive advantage through precision manufacturing.

FAQs

Q1: What is the maximum part size achievable with CNC milling?

A: CNC milling handles parts up to 4000×1500×600mm using standard equipment. For larger components, multi-setup strategies or specialized gantry mills provide solutions.

Q2: How does CNC milling ensure surface finish quality?

A: Controlled feed rates, toolpath optimization, and post-processing (like bead blasting) achieve surface roughness of Ra 1.6μm or better, meeting critical aerodynamic and medical requirements.

Q3: Is CNC milling suitable for high-volume production?

A: Yes. With automated tool changers and pallet systems, CNC milling supports batch sizes from prototypes to mass production, offering scalability unmatched by manual methods.

Q4: What file formats are required for CNC milling quotes?

A: Standard formats include STEP, IGES, or STP files containing 3D geometry. For precision parts, provide GD&T drawings to specify tolerances and critical features.

Q5: How to validate CNC milling part accuracy?

A: Use CMM inspections aligned with ASME Y14.5 standards, comparing measured dimensions to CAD models with statistical process control for comprehensive validation.

Author Bio

The technical insights in this article are backed by decades of precision manufacturing experience at LS Manufacturing, where CNC and multi-axis machining processes are refined under ISO 9001 and AS9100D certifications. Engineers looking to implement these secrets can request a complimentary Design for Manufacturability (DFM) analysis to identify optimizations in design, materials, and machining strategy.