The expansion of the pet food market correlates with the rise in the number of pets and the growing care regarding their nutrition. Manufacturers need to focus on hygiene and accurately portion food in the packaging, as these determine the quality of the end product and the operational efficacy and reputation of the company. This is particularly important for small to medium-sized businesses looking for efficiency and scale. For these companies, food packaging machines for small business operations are a cost-effective answer to their production challenges and to production standard maintenance.

Maintaining Hygiene in Pet Food Packaging

Hygiene is the most important consideration of any pet food production facility. The consequences of product contamination would include potential product recalls, legal issues, and significant loss of customer trust. A pet food packaging machine designed proactively for hygiene minimizes human interaction with food items. Some of the most important hygiene features include:

- Stainless steel: No corrosion, less cleaning effort, and extended usable life.

- Sealed conveyor systems: Protection from dust and external contamination.

- Automatic cleaning systems: The incorporation of CIP (Clean-In-Place) or full washdown features. No need for disassembly cleaning.

- Contactless Operations: Minimized interactions, limiting the risk of unwarranted interactions.

To B2B customers, touchless vending machines are the epitome of safety machine hygiene. When you sell to retailers, distributors, or export to other countries, customers expect you to comply with the International Food Safety Standards, ISO 22000, HACCP, and local veterinary food hygiene standards.

Reliable Portioning to Minimize Cost and Enhance Profit Margins

The level of accuracy in pack sizes in pet food packaging influences profitability and customer retention. Overfilled packs are costly while underfilled packs lead to complaints and loss of customers. Many small food packaging machines made today come with highly automated precision portion control packaging. For example, you can have:

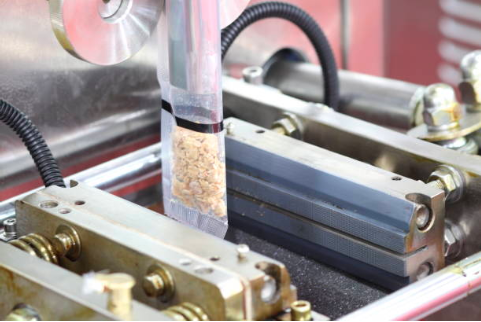

- multi-head weighers – ideal for pre-measuring and controlling packaging of irregular or granulated pet food.

- Volumetric fillers – for consistency in measure control packaging of dry and semi-moist pet food.

- Auger fillers – for accurately measuring powdered supplements or dry additives for control packing.

Portion control pre-packaged pet food assists in minimizing waste, optimising the management of stock, and creating stable pet food prices. Small businesses have reduced operational cost and elevated profit with these features.

Different Types of Machines for Pet Food Packaging

When it comes to the type of Pet Food Packaging Machine you want to order, you can decide based on the type of the product, the type of packaging, and the production capacity that you can handle. For each type of Pet Food Packaging Machine you also have to think about the format of the pet food, the size of the packaging, and the expected growth of the business on the packaging. There are different types of machines that can be used for pet food packaging such as:

- Vertical Form-Fill-Seal (VFFS) Machines: These machines are used to create pouches and automate the filling of pet food packaging and sealing. These machines are appropriate for smaller packaging operations.

- Horizontal Flow Wrappers: These machines are for packaging pet food in stick and bar shape packaging for more uniform food.

- Tray Sealers: These machines are directed for wet and semi-moist pet food.

- Cup and Pouch Fillers: These machines are for single-serve pet food portions. These machines are for more niche premium portions.

- Multi-Head Weighers Integrated with Packaging Lines: These machines precision weigh and pack pet food which are counted as to be less work for the employees.

When it comes to choosing the right packaging machines for pet food, one must consider the production needs, format to be packaged, the space to be used, and expansion for the future.

Automation and Production Workflow Integration

Integrating a pet food packaging machine into an automated production line enhances operational efficiency and reduces labor dependence while maintaining product quality. Continuous oversight of the portioning, sealing, and labeling processes reduces human error and enhances packaging consistency. The following features highlight the importance of automation:

- Conveyor Integration: Seamless product movement cuts downtime and boosts output.

- Sensors and Quality Control: Identify and remedy underfilled or poorly sealed packages before they exit the line.

- Robotic Handling: Accurate placement and packaging of products reduces the risk of contamination.

- Data Logging and Reporting: Production metrics, portion weights, and hygiene compliance records are kept for audits.

For small companies, scalable automation enables gradual expansion as demand for production increases. Critical process automation lowers operational activity for employees while offering quality consistency and aiding compliance with regulations.

Selecting the Right Machine for Small Business Operations

Selecting the right food packaging machine for small business entails assessing production capacity, product type, and budget constraints. The following should be taken into account when assessing available options:

- Production Volume: The machine should satisfy current demand while also anticipating future expansion.

- Product Variety: Certain machines perform different functions as well as handle different types of pet food with efficiency. Some machines even come with interchangeable parts.

- Hygiene and Compliance: Safety standards are met with constructions of stainless steel, wash down capabilities, and little human interaction is essential.

- Portioning Accuracy: Systems that fill and weigh are accurate which helps keep products consistent and reduces waste.

- Footprint and Scalability: Compact machines with modular expansion options are advantageous to small businesses with limited floor space.

- Return on Investment: Compare savings on labor, waste reduction, and higher output to upfront costs to determine savings.

Having the right machine positively impacts your operation, the quality of your products, and the reputation of your business. For B2B businesses, compliant and reliable machinery also showcases efficiency and helps obtain clients who are distributors, retailers, and institutional clients.

Advantages of Investing in Pet Food Packaging Machines

For B2B businesses, the advantages of investing in a pet food packaging machine includes:

- Consistency in Product Quality: Product standards are consistently maintained with accurate portioning and hygienic packaging.

- Operational Efficiency: Automation streamlining processes results in quicker production, and minimizing both labor costs and errors.

- Reduced Waste: Efficient packaging and precise portioning drastically reduces loss of the product and waste of packaging materials.

- Regulatory Compliance: Hygiene-oriented and accurate machines help in meeting regulations around safety and quality.

- Market Competitiveness: Quality packaging upholds premium positioning and assists in establishing market reputation.

Integrating these machines goes a long way for small businesses in the pet food market toward sustainable growth and operational continuity.

In conclusion, as the pet food market grows, alongside it increases the demand for accurate portions, operational efficiency, and hygienic packaging. Investing in a pet food packaging machine allows B2B businesses to uphold product quality, optimize processes, and mitigate operational risk. Properly chosen food packaging machines for small business allows businesses to grow while meeting the industry regulations and customer requirements.

Focusing on precision, hygiene, and packaging process automation, while also ensuring protective measures for the animals and clients, will also improve the business image and increase profits. For these small and medium businesses, the machines will greatly help in ensuring operational consistency and, most importantly, compliance and competitive edge in the market.