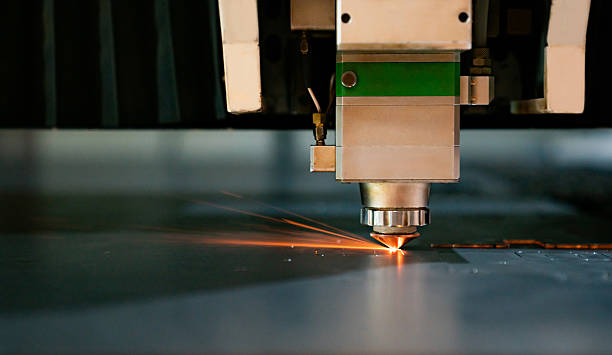

In the rapidly changing product development landscape, being able to convert an idea into a meticulously crafted component is often a project’s key differentiator. Nowadays, metal sheet laser cutting is one of the most advanced technologies enabling this. From aerospace and automotive industries to consumer electronics and architecture, laser cutting has become a mandatory part of modern fabrication.

Understanding how to operate a laser cutting machine, either personally or via an experienced custom sheet metal fabricator, will enable engineers and designers to achieve ongoing reliability, scalability, and high-performance results. This guide describes how the process works and its advantages, recommended design guidelines, and considerations for choosing a fabricator.

What Made Engineers and Designers Opt For Laser Cutting

Out of all modern cutting technologies, laser cutting still proves to be one of the most advanced. It comes equipped with various benefits when compared to traditional cutting methods. Laser cutting technology, especially on the engineering and design fronts, increases flexibility and offers unmatched precision. Unlike mechanical tools that apply force, laser cutters use focused beams of light to cut through metals with extreme accuracy. Due to reduced heat, burrs and curl formation are reduced and the cutting of detailed shapes is repeated consistently.

For sectors such as aerospace, medical device manufacturing, and electronics, where tight tolerances and clean edges are critical, this level of precision is indispensable. From stainless steel to aluminum, and even copper, thin to thick sheets of materials can be laser cut with uncompromising quality.

Compared to traditional punching and sawing methods, laser cutting allows for tighter curves and more intricate patterns. Complex cuts are performed precisely as instructed in the CAD file. The ability to rapidly prototype and modify designs without the need for costly dies or molds accelerates the development cycle significantly.

With capable custom sheet metal fabricators, engineers gain in-house design consultations and DFM, which makes it possible to strategize each component’s design and optimize it for production from the very beginning.

Key Design Principles for Laser Cut Sheet Metal

Practicing laser cutting for metal sheets involves controlling the machine’s functionalities, the work piece’s attributes, and understanding how the material would behave during the process. CAD drawing files require accurate and proper cleaning, including having the right file specifications of DXF or DWG. Closed geometries, consistent line weights, and vector paths contribute to perfect border cutting.

Designs must consider kerf—the gap produced by the laser cutting—and it sits between 0.1 mm and 0.4 mm based on material type and laser settings. Not considering kerf in the diameter of interlocking holes or slots leads to fits that are too tight or gaps that are too wide which results in the inability to assemble the components.

The thickness of materials is equally as important. Laser cutters respond well to a variety of thickness levels, but thicker metals tend to need more powerful lasers with higher processing speeds. This increases costs and production time. Selecting materials at the onset of the design phase aids in balancing functional prerequisites and manufacturing ease.

Complex geometry adds time and cost unless function dictates it. While there is ease in creating elaborate designs with laser cutting, over detailing comes with its own cost. Working together with a custom sheet metal fabricator dictates the efficiency of your design strategy and mitigates costs incurred from mistakes or adjustments.

For enclosures or chassis, engineers integrate features like vent patterns, mounting screws, and bend lines directly into the sheet. Integrated fabrication, such as forming, bending, and finishing, allow for holistic design that emphasizes not just the cut but the entire production process.

Real-World Applications and Benefits of Efficiency

The vast scope of industries has employed laser cutting because of its unparalleled flexibility, speed, adaptability, and cost efficiency. For instance, in the automotive and aerospace industries, brackets, supports, and panels are routinely laser-cut to bring strength and lightweight construction along with dimension accuracy. These components often come with intricate complex shapes that would take an impossible amount of time with traditional tools.

Moreover, laser cutting is perfect for electronic parts like circuit board housings and battery cases that require tight tolerances. Designers can test multiple iterations within a short time frame, resulting in increased market speed and innovation.

The architectural and design fields reap the benefits of laser cutting of metal sheets as well. Due to laser design freedom, decorative facades and interior panels as well as signage and custom pieces of furniture are produced with laser technology.

Custom sheet metal fabricators that offer post-processing and laser cutting services give clients a competitive advantage by streamlining workflows while easing control over quality and timelines. With great precision and speed, whether creating prototypes or undertaking large scale production runs, laser cutting proves to be a solid investment.

Integrating metal sheet laser cutting into the services offered by a custom sheet metal fabricator enhances productivity and gives them a significant competitive edge due to the fast turnaround times from design to delivery.

Choosing the Right Fabrication Partner

Making the right choice when selecting a partner greatly enhances the chances of success for a project. The partner in question should have the requisite machines, skills, and expertise needed to execute the project seamlessly from start to finish.

A partner that is constantly seeking to refine their tools and processes ought to be your first consideration. Find out if they have made the transition from using CO₂ lasers to fiber lasers. This is important because fiber lasers perform better, use lower amounts of energy, and have superior results when cutting metals. In addition, find out if they have the integrated CNC software that can process the materials and thicknesses you require.

Experience is key. An established fabricator with experience working in your region is bound to have a clearer understanding of your expectations in terms of tolerances, production standards, and your overall needs. Ask them to provide examples or even case studies that support their work.

The mentioned case studies should rely on the region or industry they claim to have experience in. Supporting these documents also highlights the flexibility that should be offered by the service provider in question. Custom sheet metal fabricators are expected to have, within their arsenal, forming, welding, hardware installation, finishing, and even assembly. This lessens the number of specialists that need to be consulted while optimizing coordination.

Do not neglect communications and support. Do they offer engineering evaluations? How fast do they respond to quote requests or design modifications? A dependable partner gives well-defined schedules, is attentive to potential issues, provides regular updates, and has a customer assistance representative focused on helping you eliminate the risk of revisions due to unnecessary expenses.

Bear in mind, as well, quality standards. In the case where components need to deliver performance targets consistently, compliance with ISO certification, internal and external quality control, and inspection procedures is mandatory. Assurance, when consequences are dire, is not a choice; it is a requirement.

Conclusion

The advent of metal sheet laser cutting has revolutionized the development of precision components by designers and engineers. It empowers innovation, efficiency of scaling, and preciseness of results across industries. When working with capable custom sheet metal fabricators, professionals can leverage this process to design around it, resulting in ideas being realized in unprecedented time, intelligently, and with greater impact.

By merging these services with custom metal sheet fabrication, unmatched precision and value is attained, whether for prototyping or entering full production. Those who adapt to evolving technologies in manufacturing will be spearheading the market, and the combination of metal sheet laser cutting paired with custom sheet fabrication is bound to exceed industry expectations.