The demand for sheet metal fabrication services has been growing for some years now. According to Maximize Market Research, the market size is expected to grow from USD 18.93 billion in 2024 to USD 25.51 billion by 2032.

Defined by various manufacturing processes for custom-built sheet metal parts, this approach offers unmatched design versatility, part quality, precision, and cost-effectiveness.

Cutting, bending, forming, and assembly processes are used to create high-quality components for diverse industries. This highly specialized strategy is common in aerospace, electronics, automotive, and architectural industries.

To unpack the details of what custom fabrication is, this article outlines the metal fabrication process, benefits, applications, and materials used.

What is Custom Fabrication?

Custom sheet metal fabrication is the processing of flat metal sheets into user-specific components using four major operations – bending, cutting, forming, and assembly.

It is different from standard fabrication in that the resulting parts have specific design specifications. Dealers, resellers, and end users turn to custom fabrication services for parts that fit their exact criteria for aesthetics, size, and performance.

What is Sheet Metal Fabrication? What are The Different Methods?

Sheet metal fabrication falls under the following four categories:

Cutting Methods – The cutting techniques in custom manufacturing include laser cutting, waterjet cutting, guillotining, and plasma cutting.

Forming Methods – Fabricators have a wide range of forming technologies to use in custom metal working, including stamping, bending, and rolling. Each of these methods has its requirements in terms of machinery, expertise, cost, and other elements.

For instance, bending is typically done on a press brake.

Joining Methods – The most common joining techniques in sheet metal fabrication services are riveting and welding.

Assembly Techniques – Assembling in sheet metal fabrication entails assembling sheet metal parts using mechanical fasteners such as bolts, screws, and rivets.

Sheet Metal Fabrication Steps

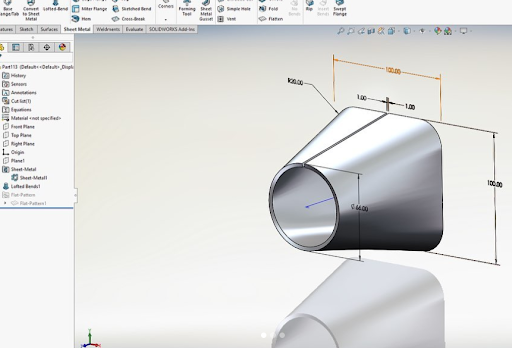

Manufacturing custom sheet metal parts is a progression from the design step through different fabrication techniques and finally, quality inspection. First, the design engineer generates the CAD design using software.

The next step is material selection, considering there is a wide variety available, including aluminum, copper, stainless steel, galvanneal steel, and the rest.

From here, the fabrication process goes to custom sheet metal forming and cutting operations. These produce the form, shape, and size of the custom sheet metal parts.

The individual parts are joined and assembled, and then put through surface treatment and quality inspection procedures.

Applications of Custom Sheet Metal Fabrication

Custom sheet metal parts are widely used in automotive, aerospace, medical, architectural, and telecommunication industries, among many others.

Manufacturers customize parts for each of these industries according to requirements for corrosion resistance, strength-to-weight ratio, versatility, and cost.

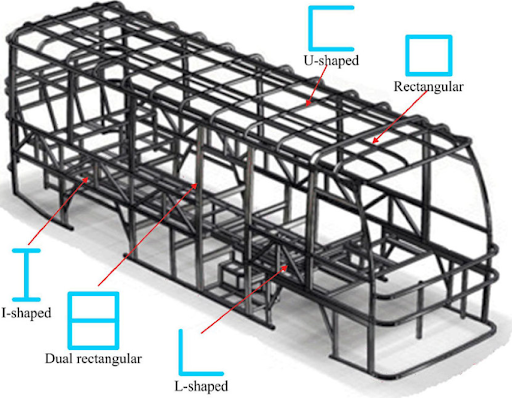

Automotive – Custom sheet metal forming and cutting produce important parts such as exhaust systems, vehicle frames, and mounts.

Aerospace – Parts include tails, fuselage, and wings

Medical – Sheet metal fabrication solves requirements for cabinets, enclosures, IV devices, and carts.

Architectural – Fabricators work with architects for sculptures, facades, ceilings, bollards, and many other components.

Telecommunication – Examples of telecommunication parts are routing systems, faceplates, amplifier chassis, and rack mounts.

Advantages of Custom Sheet Metal Fabrication

The precision, versatility, cost-effectiveness, and high quality of custom-fabricated parts appeal to a wide range of industries. Specifically, here are several advantages of this sheet metal fabrication strategy.

- Efficient use of sheet metal

- Design versatility, including complex parts

- Scalable sheet metal parts production

- Compatibility with advanced automation solutions

Limitations of Custom Sheet Metal Fabrication

Sheet metal fabrication services have to contend with a few limitations, including cost-inefficiency for low volumes, thickness constraints, springback challenges, and challenges of processing certain materials.

For the fabrication service company, identifying these project challenges is part of ensuring excellence.

How Much Does Custom Sheet Metal Fabrication Cost?

The cost of custom sheet metal fabricated parts depends on several factors, which are project-specific. These include material type, material thickness, tooling requirements, lead time, tolerance requirements, and part complexity.

Simple geometry parts from standard materials, such as cold-rolled steel, can cost markedly less than complex parts made of high-end materials, such as titanium.

Note that generally in sheet metal fabrication, the per-unit cost tends to decrease for higher volumes.

What are the Common Materials for Custom-Cut Sheet Metal Fabrication?

There is a wide variety of metal types for custom-cut sheet metal fabrication projects. Metals such as aluminum alloys, stainless steel grades, cold-rolled steel, and copper constantly feature.

Specialty options, including Inconel and titanium, are used in unique custom projects.

In Conclusion

Custom metal fabrication offers businesses a quick and effective means to manufacture bespoke parts for various industries. The flexibility, lower costs, compatibility, and innovation presented are exactly what modern enterprises require.

This differentiation is only possible if the fabrication partner has advanced capabilities and the required diversity. ProleanMFG is a top provider of sheet metal services.