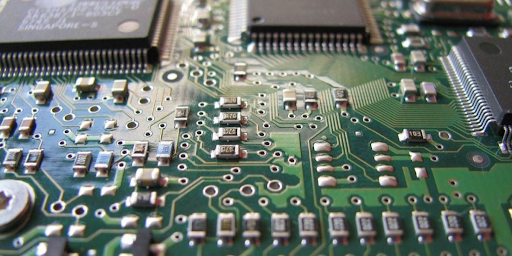

As electronic devices become more sophisticated and compact, traditional PCB designs often struggle to meet modern engineering demands. Devices today require more components, higher signal speeds, and better reliability within extremely limited space. This is where multilayer rigid flex pcb technology, combined with FastTurn PCB services, provides an advanced solution for complex electronic applications.

Multilayer rigid flex PCBs integrate multiple conductive layers within both rigid and flexible sections of a single board. When supported by FastTurn PCB manufacturing, these complex boards can be prototyped and produced quickly, enabling faster innovation and reduced time to market.

What is a Multilayer Rigid Flex PCB?

A multilayer rigid flex PCB is a circuit board that combines rigid and flexible substrates with multiple copper layers. These layers are laminated together to create a compact, high-density circuit capable of handling complex electrical requirements while still offering the flexibility to bend and fold.

The rigid areas provide strong support for components, while the flexible sections allow the board to fit into tight or irregular spaces. Multiple layers enable more complex routing, better signal control, and increased functionality without increasing the board’s size.

This type of PCB is widely used in advanced electronic devices where both performance and space efficiency are critical.

Key Features of Multilayer Rigid Flex PCBs

High Circuit Density

Multiple conductive layers allow designers to place more circuits in a smaller area, supporting complex electronic designs.

Flexible and Rigid Integration

The combination of flexible and rigid layers eliminates the need for connectors and cables between separate boards.

Improved Signal Integrity

Multilayer construction allows for better grounding, shielding, and controlled impedance, which is essential for high-speed signals.

Compact and Lightweight Design

The board can be folded or bent to fit into compact enclosures, reducing overall device size and weight.

Enhanced Reliability

Fewer interconnections mean fewer failure points, making the board more durable in demanding environments.

Applications of Multilayer Rigid Flex PCBs

Multilayer rigid flex PCBs are used in industries that demand high performance and reliability, including:

- Medical devices and diagnostic equipment

- Aerospace and defense systems exposed to vibration and extreme conditions

- Consumer electronics such as smartphones, cameras, and tablets

- Automotive control modules and sensors

- Industrial robotics and automation systems

In these applications, standard PCBs are often unable to meet the design and performance requirements.

What is FastTurn PCB?

While advanced PCB technology is essential, speed in manufacturing is equally important. FastTurn PCB refers to rapid PCB prototyping and production services that deliver high-quality boards in a very short timeframe, often within a few days.

FastTurn PCB services are especially useful during product development, where engineers need quick access to prototypes for testing and improvement.

Benefits of FastTurn PCB Services

Rapid Prototyping

Engineers can receive multilayer rigid flex PCB prototypes quickly, allowing immediate testing and validation.

Faster Development Cycles

Quick turnaround reduces waiting time and accelerates the product development process.

Quicker Time to Market

Companies can launch products faster by reducing delays in PCB production.

Efficient Design Iterations

When changes are needed, FastTurn services allow for quick modifications and re-production.

Combining Multilayer Rigid Flex PCB with FastTurn PCB

The real advantage comes from combining multilayer rigid flex PCB technology with FastTurn PCB manufacturing. Complex boards that traditionally require long production times can now be delivered rapidly for testing and refinement.

For example, a company designing a compact medical monitoring device may need a multilayer rigid flex PCB to handle complex circuitry within a small enclosure. With FastTurn PCB services, the prototype can be ready within days, allowing engineers to test performance, fit, and reliability early in the process.

This combination reduces development risks and speeds up innovation.

What to Look for in a PCB Manufacturer

When choosing a manufacturer for multilayer rigid flex PCB and FastTurn PCB services, consider the following:

- Experience in manufacturing complex multilayer rigid flex boards

- Advanced equipment for precise lamination and drilling

- Ability to offer FastTurn PCB without sacrificing quality

- Strong quality assurance and testing processes

- Technical support for design optimization

A manufacturer with expertise in both advanced PCB construction and rapid production ensures high-quality results and timely delivery.

Conclusion

As electronic products continue to demand more functionality in smaller spaces, multilayer rigid flex PCB technology offers an ideal solution. These boards provide high circuit density, improved signal performance, and exceptional design flexibility for advanced applications.

At the same time, FastTurn PCB services enable rapid prototyping and production, allowing businesses to innovate faster and bring products to market more quickly. Together, they represent a powerful combination for modern electronics manufacturing.

Whether for medical devices, aerospace systems, automotive electronics, or consumer technology, multilayer rigid flex PCBs supported by FastTurn PCB manufacturing are shaping the future of compact, high-performance electronic design.