Everything and every piece of infrastructure comes down to efficiency. It’s not about using the biggest or most expensive, it’s about choosing the best tool for the task. Three workhorses often compared against one another are the backhoe loader, the jaw crusher, and the road roller. Each is perfect for a different task, but each one’s specialty and price vary. To determine between one of these machines and invest in it, below is a breakdown that goes into types, disparities, and approximate price ranges so that you may draw up an educated conclusion.

Backhoe Loaders

The backhoe loader is a three-in-one machine. It digs, hoists, and loads and is therefore sought after for small and mid-size operations. Because it is multi-operational, it is often the first heavy machine purchased by contractors.

Here are some of the types, which you should learn to distinguish between before you break the bank purchasing

Mini – Light and compact, used for landscaping, utility, and confined city work. They sacrifice power for movability.

Standard Size and power balance, medium-scale construction, farm, or roadside work jobs.

Heavy-Duty- Bigger arms, increased horsepower, and deeper dig. They’re excavator competitors but maintain loader capability.

Types and Contrasts-

Ideal for: Situations where multifunctionality is valued over raw power. A great choice if you desire one machine that is multifaceted and yet does not require specialty crushing and compaction.

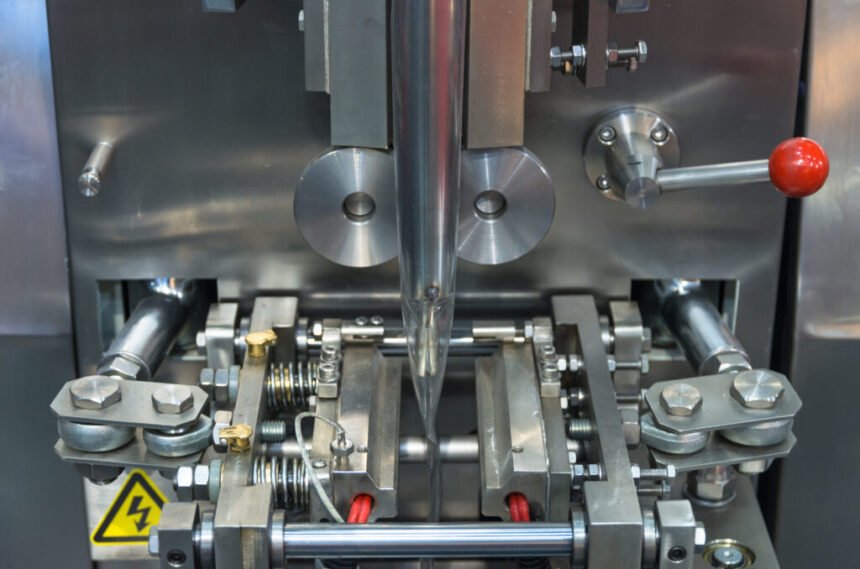

Jaw Crusher

While the backhoe loader is responsible for excavating and hauling, the jaw crusher is an expert in crushing materials. It reduces substances rock, concrete, or debris from buildings- to smaller sizes.

Best for: Projects where versatility matters more than raw power. Great choice if you need one machine to cover many jobs but don’t require specialised crushing or compaction.

Types and Contrasts:

Single-Toggle Crushers: Smaller, lightweight, and less expensive. Low capacity but cost-effective for small and medium-sized plants.

Double-Toggle Crushers: They are heavy, complex, and are for long-term, large-volume crushing. They are costly but are ideal for constant use.

Mobile Jaw Crushers: On wheels or on track, offering portability for relocatable jobs. More costly upfront, but the transport cost is recovered. Quarrying jobs, quarries, or large-scale demolition work. It is not versatile, as is a backhoe loader—it is specialised for one thing: breaking down material. But it saves enormous time and labour in treating raw materials.

Ideal for: Quarrying, pits, or large demolition work. It is not as versatile as a backhoe loader; it is single-purposed: ripping material apart. But it saves massive time and man-hours in treating raw materials.

The Finisher Road Roller

Compaction follows digging and crushing, and that is where the road roller comes in handy. It stabilizes the ground, gravel, and asphalt such that surfaces last longer and do not buckle.

Types and Contrasts:

- Smooth Drum Rollers: Ideal for granular soils and asphalt. They ensure even compaction and do not penetrate deeper layers.

- Padfoot (Sheepsfoot) Rollers: These have protrusions for kneading clay or cohésion soils. They work down deeper materials but do not provide a smooth finish.

- Pneumatic Tyre Rollers: Utilize rubber tyres to convey pressure, obtaining heavy, uniform compaction. More generally applied compared with smooth drum rollers, but less effective on very soft soils.

- Combination Rollers: With smooth tyres and drums, blending finish quality and deeper compaction.

Ideal for: Roadworks, large-scale infrastructure, and jobs requiring a hard base. While not very versatile as backhoes, rollers are absolutely vital for finish work.

Comparing Costs and Benefits

Functionality:

- Backhoe Loader: Different functions (dig, load, lift) but limited in special functions.

- Jaw Crusher: For reduction alone; highly efficient but rigid.

- Road Roller: Necessary for compaction; doesn’t dig or crush.

Types:

- Backhoes offer light, standard, and heavy-duty options.

- Crushers are either static single/double-toggle or mobile crushers.

- Rollers are of smooth drum, padfoot, pneumatic, and hybrid types.

Pricing:

- Backhoe loaders: Moderate investment, mid-five to low-six figures.

- Jaw crushers: Huge range, from small $25k devices up to $600k mobile behemoths

- Road rollers: Cheapest entry point (walk-behinds), but heavy models rival backhoes in cost.

Customising Equipment Saving Costs, Perfecting Function

Think of the decision concerning the as a workflow: Backhoe Loader for excavating and transporting> Jaw Crusher for crushing raw feed material > Road Roller for stabilization and compaction.

If you require one machine:

- Choose a backhoe loader for multi-purposes.

- Choose a jaw crusher if crushing is the core of your business.

- Choose a road roller for stability and finish on the surface.

Final Word

Backhoe loader, jaw crusher and road roller are not rivals; rather, they are players in the building phase. But budgets, size of work and priorities may force you to decide; then it is about versatility versus specialisation versus finishing.

One machine to do it all? Go with the backhoe loader. Want to crush tons of raw rock or debris? Your friend is the jaw crusher. Require durable, long-lasting roads and surfaces? Nothing compares with the road roller. Match the machine with the project stage, and you’ll not only save money but also improve efficiency.