You’re running a manufacturing business. Every day brings fresh pressure to deliver products faster, cheaper, and more tailored than your competitors. Here’s the reality: traditional production methods simply can’t keep pace with these relentless demands anymore.

But here’s what’s exciting. The 3D printing construction market is experiencing remarkable expansion, with projections showing it’ll hit $15.1 billion by 2032. This isn’t just growth; it’s a complete transformation in how smart companies tackle production challenges and stay ahead of competitors.

Understanding 3D Additive Manufacturing Technology in Today’s Market

Picture this: the additive manufacturing market is set to explode to $76.17 billion by 2030. That’s not a typo. Understanding what drives this phenomenal expansion is absolutely critical for your strategic planning. The technology has matured way beyond simple prototype creation. We’re talking sophisticated production systems that can revolutionize your entire operation.

Evolution Beyond Traditional Manufacturing Constraints

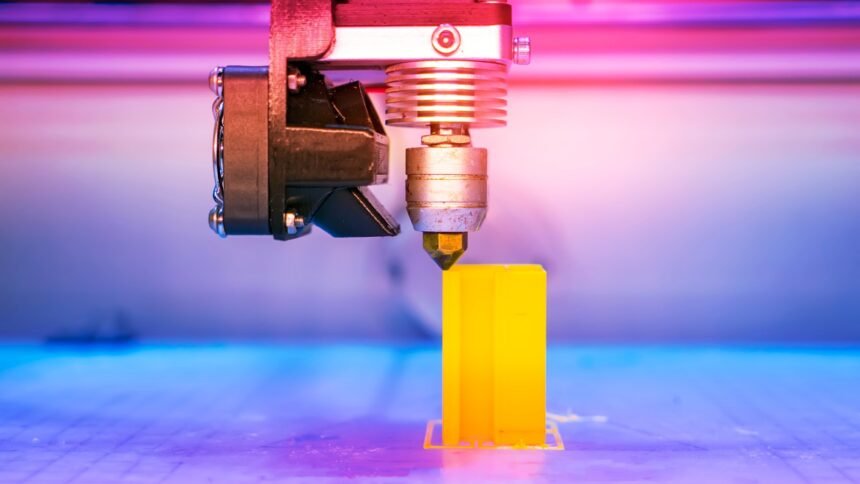

3D additive manufacturing shatters the old rules that have boxed in manufacturers for generations. Think about it differently. Instead of carving away material like traditional methods, this approach constructs products layer by layer. The result? Zero waste and geometric complexity that would make traditional engineers weep with frustration.

Gone are the days when you needed expensive tooling or lengthy setup procedures. You can now produce intricate internal architectures, hollow designs, and organic forms that would demand multiple assembly processes using conventional approaches. This newfound freedom directly translates into breakthrough design possibilities and substantial cost reductions.

Industrial 3D Printing vs. Consumer Applications

Here’s where things get serious. Professional industrial 3D printing operates in a completely different league compared to those desktop consumer models you’ve seen. When you partner with 3D Additive Manufacturing Services, you’re accessing industrial-grade machinery that handles advanced materials such as titanium, carbon fiber composites, and high-performance ceramics.

These services maintain rigorous quality controls, industry certifications, and post-processing capabilities that guarantee parts meet the most demanding industry specifications. It’s not simply about larger machines. We’re discussing precision, dependability, and material characteristics that perform flawlessly in aerospace, medical, and automotive environments.

Critical Benefits of 3D Printing for Modern Businesses

Now that you understand how additive manufacturing breaks traditional production barriers, let’s dive into the concrete business advantages driving companies across industries to embrace these services. The benefits of 3D printing stretch far beyond simple cost-cutting.

Supply Chain Resilience and Risk Mitigation

Recent global disruptions exposed just how vulnerable traditional supply chains really are. Remember those companies that depended on complex international networks? They couldn’t source essential components when crises hit.

Additive manufacturing technology enables production on demand, slashing inventory needs and eliminating those dangerous single points of failure. Parts get printed locally when you need them, rather than shipped from halfway around the world. This flexibility is something traditional manufacturing will never match.

Cost-Effectiveness Analysis Across Industries

The financial advantages vary dramatically depending on production volumes and complexity requirements. For low- to medium-volume production runs, additive manufacturing frequently delivers immediate cost benefits by eliminating tooling expenses and cutting setup times.

You’ll often discover that total ownership cost calculations favor additive methods, particularly when you factor in reduced inventory carrying expenses and accelerated time-to-market benefits. Those break-even points keep improving as technology advances and material costs drop.

Customization at Scale Without Premium Pricing

Mass customization has shifted from a luxury option to a competitive necessity. Through 3D Additive Manufacturing Services, you can offer personalized products without those traditional cost penalties associated with custom manufacturing.

Medical device manufacturers create patient-specific implants. Automotive companies produce tailored components. Aerospace firms optimize parts for specific applications—all without retooling production lines or accepting higher per-unit costs.

Additive Manufacturing Services: Choosing the Right Partner

While supply chain resilience, cost reduction, and mass customization sound compelling, achieving these advantages hinges entirely on selecting the right additive manufacturing service provider. This decision demands careful evaluation across multiple factors.

Service Provider Evaluation Criteria

Quality certifications should anchor your evaluation process. Seek out ISO 9001, AS9100 for aerospace applications, or ISO 13485 for medical devices, depending on your industry needs.

Material capabilities are absolutely crucial. Consider this: worldwide construction waste currently exceeds 1 billion tons annually, and Construction Dive reports this figure will double by 2025. Service providers offering sustainable material options and waste reduction capabilities address these mounting environmental challenges while potentially lowering your operational expenses.

Technology Stack Assessment

Different applications demand different technologies. Stereolithography delivers exceptional detail for prototypes, while selective laser sintering excels with functional parts. Metal powder bed fusion serves aerospace and automotive applications requiring strength and precision.

Your service provider should offer multiple technologies and guide you toward matching your specific requirements with the most suitable production method. This expertise prevents expensive mistakes and guarantees optimal outcomes.

Industry-Specific Applications Driving Adoption

Armed with service provider evaluation criteria, let’s examine how leading companies in the aerospace, healthcare, and automotive sectors leverage these partnerships to achieve breakthrough innovations. Real-world applications showcase the technology’s transformative potential.

Aerospace and Defense Innovations

Weight reduction creates tremendous value in aerospace applications. Every pound saved translates into fuel efficiency gains and increased payload capacity. Additive manufacturing produces lightweight components with internal structures impossible to machine conventionally.

Complex cooling channels in engine components, optimized bracket designs, and consolidated assemblies that eliminate multiple parts demonstrate the technology’s capabilities. Defense contractors utilize rapid prototyping for mission-critical components requiring fast iteration cycles.

Healthcare and Biomedical Breakthroughs

Patient-specific medical devices represent additive manufacturing’s most compelling applications. Surgeons utilize 3D-printed models for complex procedure planning, while custom implants deliver superior patient outcomes compared to standard-sized alternatives.

Bioprinting research continues advancing toward tissue engineering applications, though current commercial applications focus on surgical instruments, prosthetics, and dental solutions. The precision and customization capabilities align perfectly with healthcare’s patient-centered approach.

Automotive Manufacturing Revolution

Electric vehicle manufacturers particularly benefit from additive manufacturing’s design freedom. Battery cooling systems, lightweight structural components, and consolidated assemblies reduce vehicle weight while enhancing performance.

Motorsports teams have embraced the technology for rapid prototyping and low-volume production parts. Formula 1 teams can design, print, and test new components between race weekends, providing competitive advantages impossible with traditional manufacturing.

Emerging Trends Shaping Additive Manufacturing Technology

These industry success stories represent just the beginning—cutting-edge developments in AI integration, sustainable practices, and hybrid technologies are reshaping what’s possible in additive manufacturing. 3D printing is expected to become even more integrated into manufacturing processes, streamlining production and reducing costs.

AI-Powered Design Optimization

Machine learning algorithms now optimize part designs automatically, considering manufacturing constraints, material properties, and performance requirements simultaneously. This generative design approach produces solutions human designers wouldn’t imagine.

Predictive maintenance systems monitor printer performance, reducing downtime and improving part quality consistency. Quality control systems use computer vision to detect defects automatically, ensuring reliable production.

Sustainable Manufacturing Practices

Environmental considerations increasingly influence manufacturing decisions. Additive manufacturing’s inherent material efficiency aligns with circular economy principles, using only necessary materials rather than cutting away excess.

Recyclable materials and closed-loop systems further reduce environmental impact. Some companies achieve carbon-neutral production by combining renewable energy with efficient additive processes.

Implementation Strategies for Maximum ROI

As these transformative technologies mature, the critical question shifts from “what’s possible” to “how do we successfully implement additive manufacturing to maximize return on investment?” Success requires structured approaches and realistic expectations.

Pilot Program Development

Start with low-risk, high-impact applications that demonstrate clear value. Select projects where traditional manufacturing faces significant constraints or cost penalties.

Establish success metrics upfront, including cost savings, time reduction, and performance improvements. Document lessons learned to guide broader implementation decisions.

Integration with Existing Operations

Workflow optimization becomes critical when integrating additive manufacturing into established production systems. Quality management systems need updates to address new materials and processes.

Regulatory compliance considerations vary by industry, requiring careful attention to documentation and validation requirements. Plan integration phases carefully to avoid disrupting ongoing operations.

Future Outlook and Strategic Considerations

With a solid implementation framework in place, forward-thinking organizations must now prepare for the next wave of technological evolution and market transformation. The competitive advantages available today will become basic requirements tomorrow.

Multi-material printing capabilities will expand dramatically, enabling embedded electronics and gradient materials within single prints. Speed improvements and cost reductions will make additive manufacturing competitive with traditional methods for higher volumes.

Industry 4.0 integration will connect additive manufacturing systems with broader factory automation, enabling responsive production that adapts to real-time demand fluctuations.

Common Questions About 3D Additive Manufacturing Services

Over recent decades, 3D printing has revolutionized not just traditional manufacturing industries like aerospace and automotive but also nontraditional sectors such as art, architecture, education, entertainment, healthcare, and scientific research.

Waste Reduction: The ability to print tools, jigs, and fixtures on demand significantly cuts waste in manufacturing processes. Multi-Material Fabrication: Modern 3D printers can handle multiple materials in one build process, allowing for the creation of complex, multi-functional parts.

By utilizing 3D Additive Manufacturing Services instead of purchasing their own 3D printers, companies gain access to industrial-grade equipment, cutting-edge materials, quality certifications, and expert support—all without making large capital investments, handling equipment maintenance, or spending resources on staff training.

Taking Action on Manufacturing Innovation

By embracing 3D Additive Manufacturing Services, you’re doing much more than adopting technological improvements—you’re fundamentally reshaping how industries compete and innovate. Those who strategically implement these services will define their markets, while those who hesitate may find themselves trailing as transformation accelerates. The question isn’t whether additive manufacturing will transform your industry, but whether you’ll lead or follow that transformation.