Every industry that moves liquid needs reliable pumps. Every day, fluids including oil, gas, and chemicals need to be transferred in a safe and efficient manner. Not to mention, a reliable pump minimizes work interruptions and costly shutdowns. GTC Pumps builds mechanical seal pumps designed to handle these demanding jobs. These pumps are built to last, follow strict standards, and work well in tough environments. This article explains what makes GTC’s mechanical seal pump stand out in industries where performance and safety matter most.

What Mechanical Seal Pumps Do

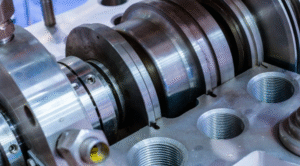

Just like all pumps, mechanical seal pumps are designed to move fluid from one place to another. The most notable difference is the way the pumps prevent leakage. A pump or seal sits between the rotating parts and the stationary parts and seals the shaft that is inside the pump while the liquid is rotating. This seal is what allows the pump to handle pressure and heat without leaking. GTC’s mechanical seal pumps are designed for continuous operation, even in systems that run all day and night.

Designed for Harsh Industrial Conditions

Hot, heavy, or even corrosive fluids are all part of daily challenges for oil refineries, chemical plants, and gas processing units. That’s where GTC Pumps comes in. GTC builds mechanical seal pumps that are designed to withstand all of that. Pumps are built in accordance with international oil and gas standards, specifically, the API 610 standards. These standards ensure pumps can handle extreme, safe, and reliable pressure. From pumping crude oil to chemical mixtures, these pumps provide continuous, hassle-free service.

Built with Quality Materials

The strength of any pump depends on its materials. GTC Pumps builds its oil and chemical pumps with high-grade metals and construction. These pumps are designed for routine maintenance for several years of use. In chemical plants, some fluids used can be acidic or hazardous, and the internal construction materials can weaken or deteriorate over time. To solve this issue, GTC uses high-quality alloys and inactive pump coatings, which protect the pump while solidifying its safe, dependable construction.

Safe Operation in Every Condition

There are hazards in oil, gas, and chemical plants. Even a minor leak in the facility can be harmful and costly to production. GTC Mechanical Seal Pumps are designed to eliminate leaks. GTC designed the seals to remain intact and prevent fluid loss even under varying temperature and pressure conditions. This protects the safety of personnel and equipment, and the safety of the environment is also enhanced. A pump that stays sealed protects the environment by containing harmful liquids.

Supporting Oil Industry Operations

GTC provides pumps for the oil industry that deliver dependable performance for mechanically sealed pumps that process crude oil, fuel, and other oil products. Oil production and refining use pumps that transport thick and hot fluids. Because the work never stops, any failure can result in big losses, which is why these pumps are trusted in situations where reliability and safety are top priorities. These pumps are designed to endure long-term, breakdown-free use regardless of whether they are on-shore or oil platforms. These pumps guarantee the safe and secure transport of oil and are unmatched in maintaining oil flow.

Helping Gas Processing Plants Stay Reliable

Gas industries also depend on pumps to move liquids used in cooling and refining. The fluids may be light, but the systems are complex. GTC Pumps’ mechanical seal pumps are well-suited for these systems. They are designed to resist vibration, maintain pressure balance, and stay stable in continuous service. That stability reduces maintenance and helps gas plants keep production on schedule. When the pump works smoothly, the whole process stays safe and efficient.

Long-Term Durability and Lower Maintenance

Lost production time occurs every hour a pump is decommissioned for repairs. GTC pumps mitigate that downtime by designing every pump with a focus on a long service life and minimal maintenance requirements. Each pump can be serviced quickly, and the time and labor costs saved are considerable. With proper maintenance and care, the pumps can work continuously for more than five years and provide a long-term, reliable, interruption-free pumping service, and that is a true indicator of a cost-effective pump for large industrial setups.

Tested for Performance and Safety

Before leaving the factory, every pump is carefully tested for flow rate, pressure, vibration, and temperature. Pumps must pass these assessments before GTC Pumps delivers them to customers. This testing guarantees that the pumps will indeed deliver to the expected performance levels for real-world applications. Besides testing for performance, testing for seal containment is equally critical, as pumps are expected to endure strenuous tasks as well. This is quality testing to build customer confidence.

Built by an Experienced Team

Behind every GTC mechanical seal pump is a skilled team. A distinct group of engineers and technicians at GTC designs, builds, and tests each model of mechanical seal pumps produced. Every model effortlessly integrates real-life industrial challenges; thus, each expert trains using industry case studies. Mechanical seal pumps need to operate reliably and consistently under harsh temperatures, high pressures, and corrosive chemicals. Every aspect of the work at GTC’s fabrication center is monitored closely and is held to the fabrication center’s high standards.

Meeting Customer Needs Across Sectors

GTC Pumps serves many types of customers. Some are in large refineries, others in small chemical plants or pharmaceutical production lines. Each has unique requirements, but all need reliable fluid transfer. GTC offers pumps that can be customized for different conditions, such as special pressure levels, liquid types, or installation spaces. This flexibility allows industries to find a pump that fits their specific systems perfectly.

A Partner in Industrial Reliability

More than just a pump maker, GTC Pumps supports industries through the full process, from design to installation guidance and technical training. Their goal is to make sure every pump performs well from the start. By working closely with clients, they help reduce mistakes during setup and improve system performance. The result is smoother operations, longer uptime, and better productivity for the whole plant.

Conclusion

GTC Pumps’ mechanical seal pumps are built for the world’s toughest jobs. Pumps maintain the circulation of operational fluids and keep working in oil and chemical processing plants. Each and every pump manufactured is geared to meet and achieve the challenging parameters of reliability, corrosion resistance, and leak-proof operation. The long life of the pumps reduces maintenance and costly unexpected downtime. They supply the reliability on which performance-critical industries depend. In environments where every second counts, GTC’s mechanical seal pumps keep the flow steady and the work going strong.