Introduction

The global pharmaceutical industry continues to expand, pushing manufacturers to adopt faster, more accurate, and more reliable production technologies. Among these technologies, tablet manufacturing equipment stands out as one of the most essential components of modern drug production. From improving output to maintaining consistency and quality, these machines ensure that pharmaceutical companies can meet both regulatory standards and market demands.

This article explores the importance of tablet manufacturing equipment, the technological advancements shaping the industry, and the benefits these systems bring to production facilities.

Understanding the Basics of Tablet Manufacturing Equipment

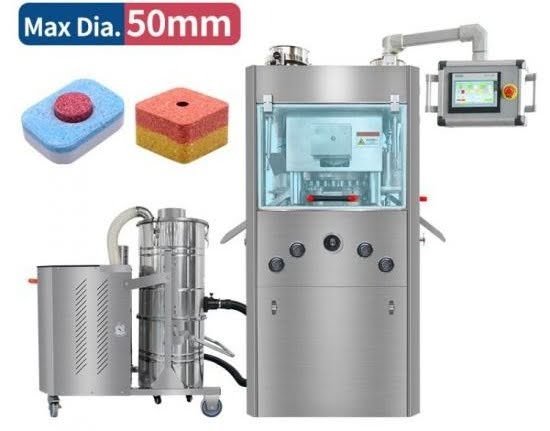

Tablet manufacturing is a highly controlled process that requires precision at every step. Equipment such as granulators, blenders, and compression machines work together to transform raw materials into uniform, high-quality tablets.

Within this workflow, the tablet press plays the central role in compressing powder into solid dosage forms, ensuring each tablet meets strict specifications for weight, hardness, and active ingredient distribution. Proper operation of this equipment is essential to achieving consistent results and maintaining product safety.

Key Components Involved in Tablet Production

Modern tablet manufacturing relies on a series of interconnected machines designed to streamline production while maintaining exacting pharmaceutical standards. Dry and wet granulation systems prepare the powder mixture; high-precision blenders ensure homogeneity; and advanced compression machines deliver repeatable tablet output.

Additional systems, such as dedusters, metal detectors, and coating machines, support the finishing phase. Each component plays a specific role, and together they form an integrated system that enhances productivity while reducing human error.

The Importance of Automation in Pharmaceutical Manufacturing

Automation has transformed the pharmaceutical industry by reducing manual labor, minimizing contamination risks, and improving product consistency. Automated tablet production equipment can monitor pressure, speed, and material flow in real time, allowing manufacturers to detect deviations instantly.

This not only improves quality control but also ensures compliance with Good Manufacturing Practices (GMP). With automation, companies can scale production rapidly while maintaining accurate documentation and process transparency.

Technological Advancements Enhancing Tablet Production Efficiency

Recent innovations in tablet manufacturing equipment have made production faster, safer, and more efficient. Modern machines are equipped with intelligent control systems, energy-efficient motors, and advanced lubrication technologies that extend machine life.

Multi-station rotary compression systems allow manufacturers to produce large batches without compromising quality. Additionally, the integration of smart sensors and data analytics supports predictive maintenance, reducing downtime and increasing overall productivity.

Quality Control and Regulatory Compliance in Tablet Manufacturing

Pharmaceutical companies operate in a highly regulated environment where product safety and consistency are top priorities. Comprehensive quality control systems must be integrated into every stage of tablet production. This includes monitoring raw materials, documenting batch records, conducting uniformity tests, and maintaining equipment calibration.

Regulatory bodies such as the FDA and EMA require manufacturers to implement robust quality management systems, making advanced tablet production equipment essential for meeting compliance standards.

Choosing the Right Equipment for Your Pharmaceutical Facility

Selecting the most suitable tablet manufacturing equipment depends on production scale, product type, and regulatory requirements. Manufacturers should consider factors such as machine speed, material compatibility, cleaning efficiency, and durability.

Reliable suppliers offer a wide range of equipment with customizable features to suit different production needs. For organizations seeking high-quality tablet manufacturing systems, trusted companies such as Rich Packing provide advanced, reliable solutions designed for modern pharmaceutical standards.

Final Thoughts

As pharmaceutical demand continues to rise, choosing dependable and high-performance equipment is more important than ever. The central role of the tablet press, along with advancements in automation, engineering, and quality control, has transformed the way manufacturers produce solid dosage forms.

In the end, by investing in modern, compliant, and intelligently designed equipment, pharmaceutical companies can strengthen their manufacturing capabilities, improve product consistency, and meet global regulatory expectations. High-quality, technology-driven solutions ensure that the industry can continue delivering safe and effective medicines to patients worldwide.