Understanding physicochemical traits is essential in deciphering the behavior and function of materials. These characteristics dictate how materials interact with their environment, process, and perform under various conditions, significantly influencing innovation and project outcomes. what is physicochemical properties? Researchers and developers keen on optimizing performances intensively explore these traits to enhance material capabilities. Crucial physicochemical properties act as the foundation for material development strategies. Their impact is transformative across industries, ranging from pharmaceuticals to electronics.

Core Physicochemical Properties That Define Material Performance

Solubility and Its Impact on Material Stability and Use

Solubility is crucial in determining how a material will interact in different environments. Materials with high solubility dissolve easily, making them ideal for applications in liquid-based systems. For example, in pharmaceuticals, drugs that dissolve quickly in the body are more easily absorbed, enhancing efficacy. In contrast, low-solubility materials might be desirable for slow-release applications or where water resistance is needed. Stability is paramount; soluble materials must maintain integrity in solvents to prevent breakdown. Overcoming solubility challenges involves chemical modifications or using solubility-enhancing excipients. Thus, solubility not only affects ease of use but also dictates the scope of material applicability across industries.

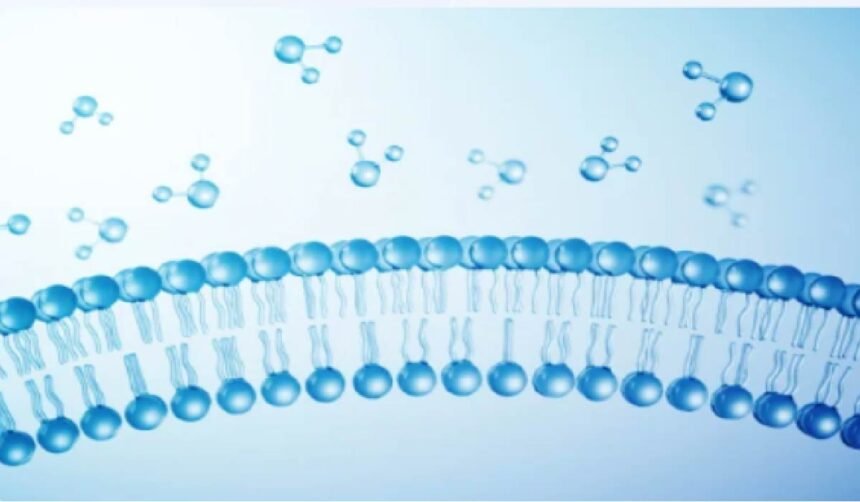

Lipophilicity and Partition Coefficients in Material Design

Lipophilicity describes a material’s affinity for fats over water, usually quantified by partition coefficients. High lipophilicity is crucial in creating materials that need to penetrate lipid-rich environments, such as biological membranes. For drug development, optimizing lipophilicity ensures effective delivery to target sites, balancing solubility to avoid accumulation and toxicity. Materials heavily influenced by lipophilicity find applications in coatings, waterproof materials, and liposomal formulations. Partition coefficients serve as indicators for predicting material distribution and interactions within biological systems and environments. Consequently, mastering lipophilicity in material design leads to tailored functionalities by regulating absorption, distribution, retention, and elimination.

Ionization, pKa, and Charge-Driven Behavior in Materials

Ionization affects how materials respond to environmental pH levels, pivotal in sensitive sectors like pharmaceuticals. The ionization constant, or pKa, indicates at what pH a substance gains or loses a proton, influencing solubility and permeability. Materials designed with appropriate pKa values perform optimally at desired pH levels, maintaining stability and function. When designing drugs, correct ionization ensures adequate solubility across the gastrointestinal tract, improving absorption rates. Charged states of materials impact binding and attraction to other molecules, driving reaction dynamics in material synthesis and processing. Ionization ensures materials perform predictably across varying pH environments.

Structural and Thermal Traits Shaping Material Behavior

Molecular Weight and Size Effects on Material Function

Molecular weight significantly dictates a material’s processing and performance attributes. Larger molecules generally exhibit higher melting points and viscosities, affecting the ease of processing. In polymers, increased molecular weight enhances tensile strength and elasticity, crucial for packaging, textile, and automotive industries. However, excessive size can impede solubility and diffusion rates, requiring balance during material design. Weight variations impact the responsiveness and adaptability of materials in complex applications. Thus, understanding and controlling molecular weight and size are key in fine-tuning material functionalities, ensuring performance requirements align with industry needs.

Melting Point and Thermal Stability in Real-World Conditions

The melting point is a clear indicator of thermal stability, heavily influencing material selection for applications exposed to temperature extremes. Higher melting points usually correlate with enhanced durability and resistance, important for aerospace, construction, and electronics. Materials must retain physical and chemical integrity upon reheating and cooling. Low thermal stability could lead to deformation or failure under stress. Incorporating materials with varied melting points allows for tailored thermal behaviors and protective barriers against thermal degradation. Predicting material performance through melting point analysis helps achieve desired durability, ensuring operational reliability even in demanding environments.

Crystallinity vs Amorphous State in Material Performance

Crystallinity influences mechanical strength, transparency, and material processing. Highly crystalline materials display superior tensile strength and chemical resistance, advantageous for structural applications. Amorphous materials, offering unique optical properties and processing ease, feature prominently in products requiring translucency and flexibility. The morphological state impacts how substances interact with their environment; crystalline structures offer predictability in performance. Amorphous forms adapt across diverse applications, where transparency and rapid absorption are necessary, such as in optics and pharmaceuticals. Consequently, balancing crystallinity and amorphous traits in materials affects versatility and application-specific performance.

Measurement, Optimization, and Practical Applications

Analytical Methods for Physicochemical Profiling (WuXi AppTec)

Effective physicochemical profiling involves precise analytical methods to reveal material properties. WuXi AppTec pioneers advanced testing systems, using spectroscopy, chromatography, and other techniques to analyze solubility, thermal properties, and molecular weight. These analyses are critical for research and quality assurance, ensuring materials meet industry standards without compromising quality. Robust profiling allows partners to detect anomalies, optimize processes, and innovate confidently. Real-time surveillance and data interpretation transform raw data into actionable insights. Employing cutting-edge analytical technology empowers researchers and developers to refine, adapt, and predict material behavior accurately, driving advancement in various sectors.

Optimizing Physicochemical Traits for Development Success

Optimization forms the cornerstone of material development, adapting physicochemical traits for desired performance. Techniques include chemical modification, blending, or the use of additives. Tailoring solubility and thermal properties ensures materials excel in specific conditions, enhancing usability and shelf life. Innovation demands a holistic approach, assessing how traits like molecular weight or crystallinity impact end-use applications. Streamlined processes enhance efficiency and performance, minimizing the risk of failure. Leveraging robust optimization strategies secures competitive advantages, fostering innovation and successful product development across industries. Strategic trait manipulation results in products that consistently meet or exceed expectations.

Linking Physicochemical Data to Predictive Performance Models

Harnessing physicochemical data facilitates the development of predictive performance models. Quantitative analysis predicts how materials behave under different conditions, guiding strategic decisions. These models simulate real-world applications, reducing trial-and-error in research and development. Data-driven insights enhance the predictability of performance outcomes, optimizing material selection criteria. Predictive modeling allows developers to foresee challenges and opportunities, tailoring materials to fit precise specifications. The integration of data into digital models equips researchers with the tools to visualize potential scenarios, ensuring materials perform optimally upon market launch, ultimately accelerating innovation and commercial success.

Conclusion

Physicochemical traits serve as the foundation for understanding and improving materials’ performance across various applications. These properties influence crucial characteristics like stability, solubility, and thermal response, determining material suitability in diverse conditions. Mastering these traits leads to optimized materials capable of meeting specific demands, driving innovative outcomes. Thorough comprehension supports efficient development, enabling precise application targeting. Therefore, leveraging physicochemical knowledge is vital for sustained progress, reliability, and success in material design and application, empowering researchers and developers to realize groundbreaking advancements and solve pressing challenges in numerous fields.